Introduction

■The double girder gantry crane is an advanced lifting system featuring two parallel girders mounted atop a robust framework that travels along dedicated crane rails. Equipped with a heavy-duty electric crab hoist trolley or motorized open-drum winch as its primary lifting mechanism, this crane ensures precision and durability in demanding applications. The trolley operates on rails fixed to the upper flange of the double girders, enabling smooth horizontal movement, while the entire gantry structure—supported by one or two reinforced legs integrated with end beams—transverses longitudinally via motorized end carriages along ground-mounted tracks.

■Engineered for severe-duty cycles, double girder gantry cranes excel in heavy-load handling, high-intensity operations, and specialized industrial environments such as steel mills, shipping yards, and power plants. Their design surpasses single girder configurations in both structural integrity and functional complexity, offering enhanced load-bearing capacity, extended span capabilities, and adaptability to extreme working conditions.

■Critical design elements include optimized box-girder or truss-style main beams, fatigue-resistant welded connections, and precision-aligned rail systems, all rigorously validated through FEM analysis and ISO-certified quality controls. While customization options for span, lifting height, and operational speed require detailed engineering consultation, our commitment remains unwavering: we prioritize safety and longevity over cost-cutting compromises, ensuring every crane delivers decades of reliable service. For technical specifications, load charts, or project-specific feasibility studies, contact our engineering team to explore tailored solutions for your lifting challenges.

Application

Double girder gantry crane is widely used in indoor and outdoor scenes in the industrial field due to its excellent lifting capacity, structural stability and environmental adaptability. Whether it is precision material handling in closed workshops or heavy cargo loading and unloading in open fields, its double-beam design can provide efficient and safe solutions, becoming an indispensable core equipment in modern manufacturing, logistics and heavy industry.

◒Indoor application

☑In workshops, warehouses and factories, double girder gantry crane is used for precise transfer of production line materials, equipment installation and maintenance, and finished product stacking. Its compact design and high positioning accuracy can adapt to narrow spaces and support high-frequency and high-precision operation requirements in industries such as automobile manufacturing, mechanical processing, and electronic assembly.

☑On automated production lines, cranes can integrate intelligent control systems and cooperate with slings or electromagnetic suction cups to achieve unmanned material flow, greatly improving production efficiency.

◓Outdoor application

☑As a heavy logistics hub equipment, double girder gantry crane undertakes tasks such as container loading and unloading at port terminals, steel coil/plate transfer at steel mills, ore loading at mines, and hull segment lifting at shipyards. Its wind-resistant and rust-proof structure and weather-resistant design can cope with harsh working conditions such as high temperature, humidity, and dust.

☑In special scenarios, the crane can be equipped with grabs, clamps or special lifting equipment to meet the customized handling needs of bulk cargo (such as sand and gravel, coal), long pieces (such as pipelines, bridge components) or dangerous goods (such as chemical tanks), covering diversified fields such as energy, construction, and chemicals.

From light industry to heavy industry, from indoors to outdoors, heavy duty gantry cranes continue to empower global industrial productivity with their high load capacity, flexible configuration and all-weather operation performance. Its modular design can also be customized according to span, lifting height and working level to ensure that safety and economy can be taken into account under complex working conditions, becoming a strategic equipment for enterprises to optimize logistics efficiency and reduce operating costs.

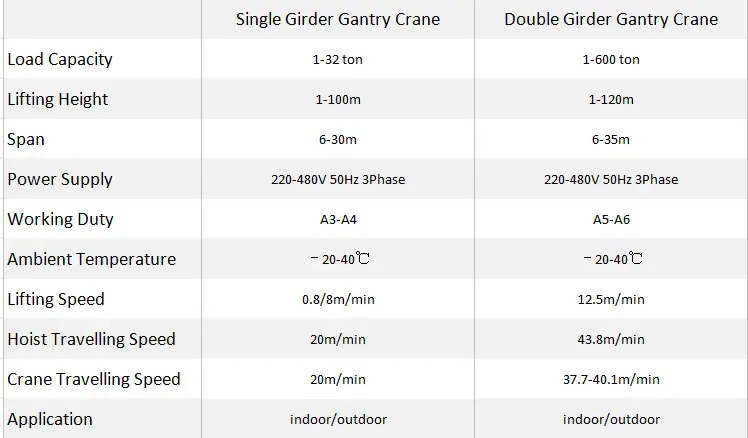

Comparison of Single Girder Gantry Crane and Double Girder Gantry Crane

Why Choose SEVENCRANE

Customized Engineering for Cost Efficiency

We deliver precision-engineered double girder gantry cranes tailored to your operational environment. Our solutions optimize structural design, lifting capacity, and spatial utilization through collaborative feasibility studies, ensuring compliance with your workflow while minimizing lifecycle costs.

Certified Quality, Built to Endure

Every crane embodies our ISO 9001/CE-certified manufacturing rigor, from stress-tested girders to fatigue-resistant drive systems. Components undergo 200+ quality checkpoints, including load simulation and 3D FEM analysis, guaranteeing durability in extreme conditions like Class A8 (ISO 4301) duty cycles.

Lifetime Support Partnership

Our 24/7 global technical network and decade-long spare parts commitment ensure seamless operation, reducing downtime by up to 30% compared to industry benchmarks.

For inquiry, please send email: info@zidraxcranes.com