Introduction

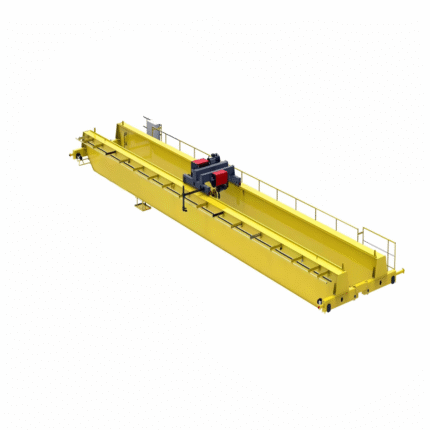

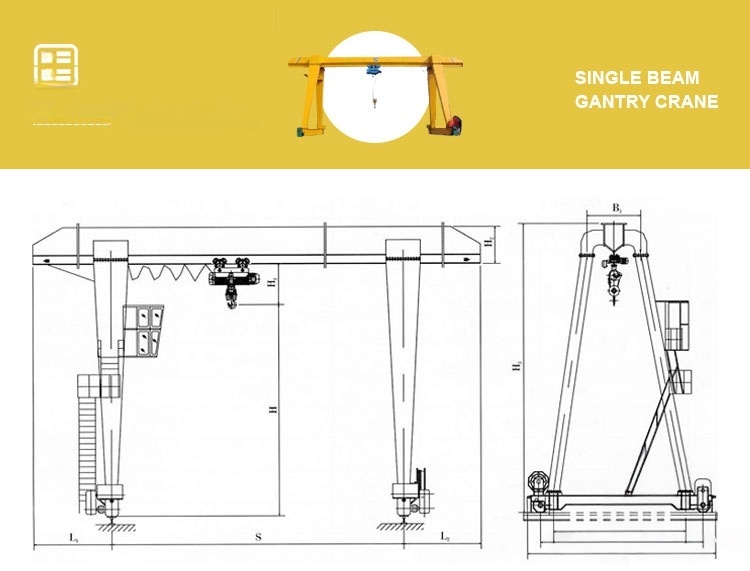

❐The single girder gantry crane is a common industrial lifting equipment with a single-beam structure on the top and runs on the track. It is usually equipped with an electric wire rope hoist or an electric chain hoist as required as the lifting mechanism. The hoist is suspended under the main beam and moves with it. The main beam of the crane is supported by one or two legs and travels along the track through the end beam.

❐Since the maximum lifting capacity of the electric hoist is 20 tons, the lifting capacity of the single girder gantry crane is usually no more than 20 tons. It is suitable for a variety of indoor and outdoor scenes, such as docks, cargo yards, warehouses and construction sites, and can complete most material handling work, so it is very popular.

❐The single girder gantry crane supports six-way movement – the hoist runs left and right, the hook lifts up and down, and the whole machine moves forward and backward along the track. If the stroke is long, it can be equipped with a cable reel to effectively manage the retraction and release of the power supply cable. In addition, some single girder gantry cranes have an optional cantilever design to lift the load outside the track and enhance the flexibility of operation.

❐The crane is mainly composed of a steel structure gantry, a walking mechanism, an electric hoist, and an electrical control system. As an experienced manufacturer, we can provide gantry cranes of different specifications and always adhere to high quality and reasonable prices to ensure that customer needs are met.

Benefit

①Cost-effective: Single girder gantry cranes are cheaper than double girder gantry cranes because they require less material to build. This makes them a great choice for small and medium-sized businesses that need to operate on a tight budget.

②Versatility: Single girder gantry cranes can be used for a wide range of applications due to their flexibility. They can be customized with a variety of attachments, such as booms, magnets, and hooks to handle different types of loads.

③Easy to install and maintain: Single girder gantry cranes are relatively easy to install and maintain with minimal downtime. They also have fewer moving parts than double girder gantry cranes, which reduces maintenance costs.

④Space-saving: Single girder gantry cranes require less vertical space than double girder gantry cranes, making them ideal for facilities with limited headroom.

Custom Options

➊Hoist: The hoist is a key component of a gantry crane, available as an electric wire rope hoist or electric chain hoist. It can be configured with dual hoists to lift a single heavy load together or operate independently for handling two smaller loads simultaneously.

➋Control System: Our gantry crane offers pendant, remote, or cabin control options. The wireless remote enhances safety and efficiency by allowing operators to move freely for better visibility. The cabin control, mounted on the crane, enables direct operation via switches and controls.

➌Weather Protection: Additional features like canopies, enclosures, and heaters safeguard the crane from harsh weather. An optional rail clamp secures outdoor gantry cranes in stormy conditions, while a wind safety system monitors outdoor operations.

➍Safety Features: To ensure secure operation, the crane is equipped with limit switches, overload protection, emergency stop buttons, and warning horns.

➎Variable Frequency Drive (VFD): The VFD system regulates motor speed and torque, improving energy efficiency and minimizing component wear.

➏Anti-Collision System: Sensors and warning signals help prevent accidents by detecting nearby cranes and alerting operators in shared workspaces.

Our Service

SEVENCRANE’s professional service team consists of highly skilled and experienced technicians who have undergone rigorous training and certification in equipment installation, maintenance, repair and troubleshooting. Our service team will provide you with gantry crane solutions that meet your lifting needs based on your actual working conditions.

FAQ

☞Why choose a single girder gantry crane?

If your facility lacks support columns or you are leasing a building, a gantry crane is a cost-effective choice as it eliminates the need for structural columns and is easier to install and dismantle. Gantry cranes are also ideal for outdoor applications.

☞Which type of gantry crane is best for us?

If your crane will operate in open areas with strong winds, a truss-type (lattice) gantry crane is recommended for better wind resistance.

If you need a cantilever to handle large-sized loads, an L-type gantry crane is a suitable option.

☞Can I install a gantry crane without excavating the foundation?

Yes. If the concrete floor is at least 20 cm thick, excavation is unnecessary. Instead, steel plates can be anchored to the concrete using bolts, and the rails can be welded onto the plates.

☞Do you provide spare parts for gantry cranes?

Yes. As a gantry crane manufacturer, we supply all necessary spare parts, including motors, hoists, wheels, trolleys, hooks, rails, girders, enclosed busbars, and grabs.

For inquiry, please send email: info@zidraxcranes.com